Product Description

The M12 Male and Female Plug Waterproof Connector represents the gold standard in industrial connectivity solutions, specifically engineered for critical applications requiring reliable performance in challenging environments. This IP67-rated connector system features precision-machined components with superior waterproof capabilities, making it an essential component for industrial automation, sensor networks, and outdoor equipment. The male and female plug design ensures secure mating with positive locking mechanism, while the 360° EMI shielding provides exceptional signal integrity in electrically noisy environments. Manufactured with high-temperature resistant materials and gold-plated contacts, this connector series delivers unmatched reliability in moisture-prone, dusty, or vibration-intensive applications.

Product parameters

Product Model :M12

Number of cores :2/3/4/5/8 pins

Shell material: Nylon

Rated voltage :250V

Rated current :10 to 20A

Waterproof rating :IP67/68

Operating temperature :-40℃±105℃

Cable diameter: 4.5- 8.2

Connection method: Threaded connection

Product Features

Superior Waterproof Performance

Advanced triple-seal design incorporates silicone rubber seals at the interface, cable entrance, and between connector components, ensuring complete waterproof integrity even under high-pressure washdown conditions.

Enhanced EMI/RFI Protection

Full 360° shielding with metal shell construction provides excellent electromagnetic and radio frequency interference protection, crucial for maintaining signal accuracy in industrial environments.

Mechanical Reliability

The screw-type coupling mechanism with metal locking nut ensures vibration-resistant connections that maintain integrity under continuous mechanical stress and frequent mating cycles.

Corrosion Resistance

Stainless steel components and gold-plated contacts (minimum 0.2μm thickness) provide exceptional resistance to corrosion, oxidation, and chemical exposure.

Quick-Installation Design

Tool-free assembly system with color-coded wiring indicators reduces installation time by 40% compared to traditional Industrial Connectors.

Versatile Configuration Options

Available in 3, 4, 5, and 8-pin versions with A-coded, B-coded, and D-coded options for various industrial protocols including Ethernet, PROFINET, and IO-Link.

Product Advantages

Unmatched Environmental Protection

The IP67 rating ensures reliable operation in the most demanding conditions, including exposure to water, oils, chemicals, and extreme temperatures, significantly reducing system downtime.

Signal Integrity Assurance

Combination of gold-plated contacts and comprehensive EMI shielding guarantees minimal signal loss and data transmission errors, essential for precision sensor applications.

Reduced Total Cost of Ownership

The robust construction and high-quality materials provide extended service life, reducing replacement frequency and maintenance costs by up to 60% compared to Standard Connectors.

Global Compliance

Certified according to international standards including IEC 61076-2-101, ensuring compatibility and performance reliability across global markets.

Flexible Application Support

Compatible with various cable types including PUR, PVC, and rubber cables, supporting both power and data transmission requirements in diverse industrial settings.

Application Fields

Industrial Automation

Robot arm connections and control systems

PLC and controller interconnections

Motor and drive system interfaces

Assembly line sensor networks

Process Control Systems

Pressure and temperature sensors

Flow measurement equipment

Level detection systems

Analytical instrumentation

Transportation Infrastructure

Railway signaling equipment

Traffic control systems

Vehicle sensor networks

Marine navigation equipment

Renewable Energy

Solar panel monitoring systems

Wind turbine sensor connections

Battery management systems

Power conversion equipment

Building Management

HVAC control systems

Security and access control networks

Energy monitoring equipment

Emergency lighting systems

Food and Beverage Processing

Washdown-area equipment

Packaging machinery sensors

Quality control instrumentation

Process monitoring systems

Frequently Asked Questions (FAQ)

Q1: What is the difference between A-code and B-code versions?

A: A-code connectors are typically used for sensors and DC power, while B-code versions are designed for PROFIBUS applications. The coding prevents mismating of incompatible systems.

Q2: Can these connectors be used in outdoor applications?

A: Yes, the IP67 rating and UV-resistant materials make them suitable for outdoor use, including exposure to weather elements and temperature variations.

Q3: What is the expected service life?

A: With proper installation and usage, these connectors typically provide 5-8 years of reliable service, even in demanding industrial environments.

Q4: Are custom cable lengths available?

A: Yes, we offer custom cable assembly services with various lengths and jacket materials to meet specific application requirements.

Q5: How do I ensure proper waterproof sealing?

A: Ensure all sealing surfaces are clean, the cable gland is properly tightened, and the coupling mechanism is fully engaged until positive lock is achieved.

Q6: Can these connectors be used in hazardous locations?

A: While they provide excellent protection, for hazardous locations requiring explosion-proof certification, please consult our specialized product range.

Q7: What maintenance is required?

A: Minimal maintenance is needed. Periodic visual inspection and cleaning of contacts are recommended in harsh environments.

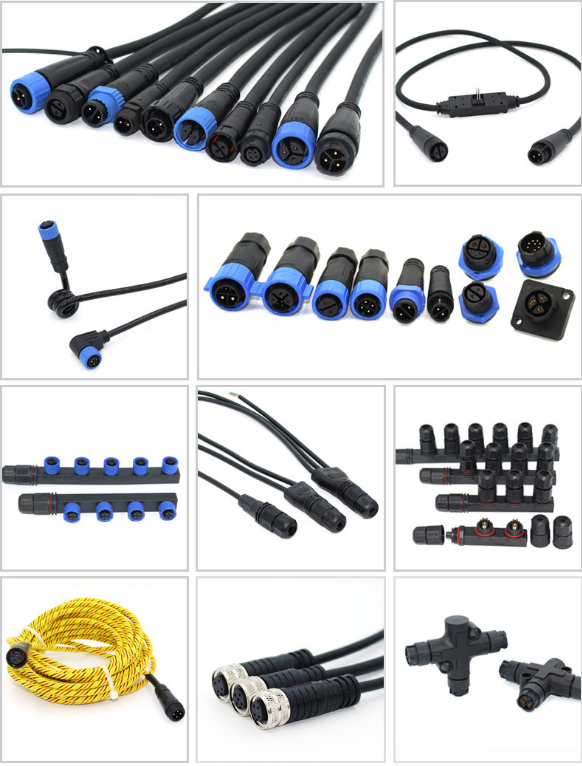

Display of waterproof plug

Contact person: Mr. Bei

Mobile phone: +86 13378428166

whatsApp: +86 13378428166

Address:2F, Bldg B, Guancheng High-Tech Industrial Park,

No. 2, Xiguangyue 1st Road, Xinhu Street,

Guangming District, Shenzhen, 518107

Copyright © 2025 Shenzhen Jiayunkang Technology Co., Ltd. All Rights Reserved. support: huaqi

This website uses cookies to ensure you get the best experience on our website.