Product Description

The M12 Circular Metal Thread Waterproof Connector represents the pinnacle of reliability in industrial connectivity solutions. Engineered for extreme environmental conditions, this premium connector combines military-grade durability with advanced sealing technology to deliver uncompromised performance in the most challenging applications. Featuring a precision-machined stainless steel threaded coupling mechanism and IP68 protection rating, this connector ensures absolute protection against moisture, dust, chemicals, and mechanical stress. The innovative triple-sealing system incorporates silicone rubber seals, precision O-rings, and thread locking compound to create an impervious barrier against environmental contaminants. Designed for industrial automation, process control, and outdoor applications, this connector maintains signal integrity and electrical performance even when subjected to temperature extremes, vibration, and frequent mating cycles.

Product parameters

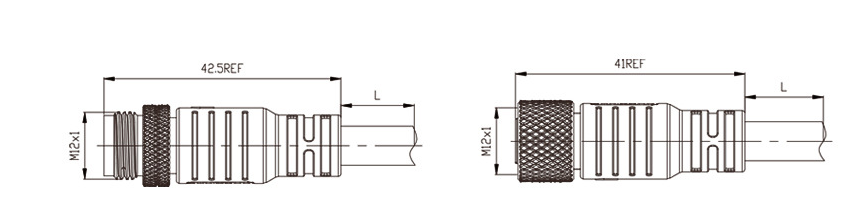

Product Model :M12

Number of cores :4/5/8/12 pins

Shell material: Nylon

Rated voltage :125V

Rated current :1.5-4A

Waterproof rating :IP67/68

Operating temperature :-40℃±85℃

Cable diameter :OD≤ 7mm

Connection method: M12 thread

Product Features

Military-Grade Sealing System

Advanced triple-sealing technology combining radial silicone sealing, axial compression sealing, and thread interface sealing ensures complete environmental protection. The self-lubricating sealing materials maintain performance across extreme temperature ranges.

Stainless Steel Threaded Coupling

Precision-machined 316 stainless steel threads provide exceptional corrosion resistance and mechanical strength. The anti-galling thread design prevents seizing and cross-threading, ensuring smooth mating even after hundreds of cycles.

Superior EMI/RFI Protection

360° electromagnetic shielding with coverage exceeding 90dB attenuation from 100MHz to 1GHz. The seamless metal shell design eliminates leakage points, providing unparalleled electromagnetic compatibility.

High-Reliability Contacts

Gold-plated beryllium copper contacts with redundant contact points ensure maximum reliability. The multi-finger contact design provides six points of contact per pin, guaranteeing signal integrity under vibration and shock.

Environmental Resilience

UV-resistant housing material with ozone and chemical resistance. The connector withstands exposure to fuels, solvents, hydraulic fluids, and cleaning agents without degradation.

Quick-Deployment Design

Color-coded coupling nuts and tactile position indicators enable quick mating in low-visibility conditions. The anti-rotation key prevents incorrect orientation during connection.

Product Advantages

Unmatched Reliability

The combination of military-grade materials and precision engineering delivers 99.9% reliability rating over 10,000 operating hours, reducing system downtime and maintenance costs.

Extended Service Life

Superior materials and construction provide 5x longer service life compared to standard M12 Connectors, withstanding over 500 mating cycles while maintaining sealing integrity.

Performance Consistency

Maintains stable electrical characteristics across entire temperature range with less than 0.5mΩ variation in contact resistance and consistent impedance matching.

Installation Efficiency

Tool-less assembly and visual alignment features reduce installation time by 60% compared to traditional Threaded Connectors. The snap-in contact design eliminates special tool requirements.

Cost Optimization

Reduced maintenance requirements and extended service life lower total cost of ownership by up to 40% over conventional Industrial Connectors.

Application Fields

Extreme Environment Industrial

Offshore drilling equipment

Mining machinery controls

Chemical processing plants

Steel mill automation systems

Transportation Infrastructure

Railway signaling systems

Tunnel monitoring equipment

Bridge structural sensors

Traffic control systems

Military and Aerospace

Ground support equipment

Vehicle control systems

Surveillance equipment

Communication devices

Energy Sector

Wind turbine controls

Solar tracking systems

Oil pipeline monitoring

Power distribution equipment

Marine Applications

Shipboard instrumentation

Docking control systems

Underwater monitoring

Navigation equipment

Building Management

Elevator control systems

Fire safety equipment

Security systems

HVAC controls

Frequently Asked Questions (FAQ)

Q1: What differentiates this from standard M12 connectors?

A: Our connector features military-grade stainless steel threading, IP68 protection (not just IP67), and enhanced EMI shielding, making it suitable for extreme conditions where Standard Connectors fail.

Q2: Can it withstand high-pressure washdowns?

A: Yes, the connector is designed to withstand high-pressure cleaning (up to 1000 PSI) and steam cleaning procedures common in food processing and pharmaceutical applications.

Q3: Is the connector explosion-proof?

A: While offering superior sealing, for hazardous locations requiring explosion-proof certification, please consult our specialized ATEX-compliant versions.

Q4: What maintenance is required?

A: The connector requires minimal maintenance. Recommend visual inspection every 6 months in harsh environments and re-torquing of coupling nut after 100 mating cycles.

Q5: Are custom lengths and configurations available?

A: Yes, we offer complete customization including cable length, jacket material, connector orientation, and special pin assignments.

Q6: How does it perform in saltwater environments?

A: The 316 stainless steel provides excellent corrosion resistance in saltwater applications, making it ideal for marine and offshore use.

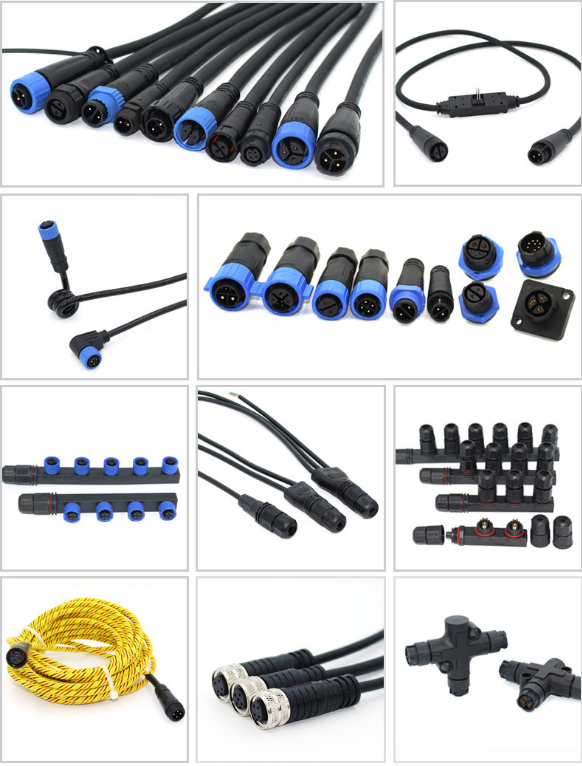

Display of waterproof plug

Contact person: Mr. Bei

Mobile phone: +86 13378428166

whatsApp: +86 13378428166

Address:2F, Bldg B, Guancheng High-Tech Industrial Park,

No. 2, Xiguangyue 1st Road, Xinhu Street,

Guangming District, Shenzhen, 518107

Copyright © 2025 Shenzhen Jiayunkang Technology Co., Ltd. All Rights Reserved. support: huaqi

This website uses cookies to ensure you get the best experience on our website.