In the demanding worlds of industrial automation, robotics, and outdoor lighting, reliable connectivity is non-negotiable. Our M8 4-pin IP65 Male and Female Connector is engineered to deliver unwavering performance precisely where failure is not an option. This robust, compact connector ensures that your machinery, sensors, and devices maintain secure power and signal transmission, even when exposed to dust, moisture, and constant vibration.

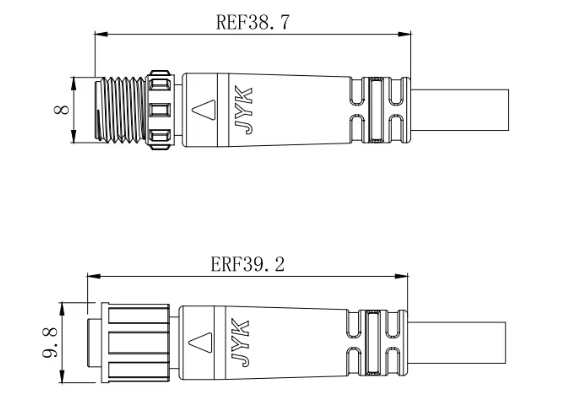

The M8 4-Pin Connector system is a cornerstone of modern industrial interconnect solutions. Designed with a compact 8mm threaded mating diameter, this connector pair is ideal for applications where space is limited but performance is critical. The male (plug) and female (receptacle) counterparts feature a precision-engineered 4-pin configuration, supporting a mix of power and signal transmission within a single, robust unit.

Constructed from high-grade materials, the connector body is typically made from durable PBT plastic for excellent chemical and impact resistance, while the pins are brass with gold-over-nickel plating to ensure superior conductivity and corrosion resistance. The integrated locking thread mechanism guarantees a secure and stable connection, preventing accidental disconnection in high-vibration environments. The IP65 rating certifies that these connectors are fully protected against dust ingress and low-pressure water jets from any direction, making them suitable for use in wash-down areas and outdoor applications.

Rugged IP65 Protection: Completely sealed against dust and protected from water jets, ensuring reliable operation in wet and dirty conditions.

4-Pin Configuration: Versatile design capable of handling both power (typically up to 250V) and signal/data lines, simplifying wiring harnesses.

High-Vibration Resistance: The secure screw-locking mechanism prevents loosening, maintaining connection integrity in environments with constant movement or shock.

Compact M8 Form Factor: Its small size saves valuable space in control cabinets, on machinery, and in compact device designs.

Premium Contact Materials: Brass pins with gold plating offer low contact resistance, high current-carrying capacity, and long-term corrosion resistance.

Flexible Cable Options: Available with PVC or PUR cable jackets, providing a choice between standard durability and superior oil, chemical, and abrasion resistance.

Shielded Version Available: Options for electromagnetic interference (EMI) shielding to protect signal integrity in electrically noisy environments.

Why choose our M8 Connector over alternatives? The advantages translate directly into enhanced system reliability and reduced total cost of ownership.

Maximized Uptime: The IP65 rating and robust build quality drastically reduce downtime caused by connection failures due to environmental factors. This leads to higher productivity and lower maintenance costs.

Simplified Installation & Maintenance: The clear pin numbering and user-friendly design allow for quick and error-free field termination. Their standardized nature makes replacements and repairs straightforward.

Enhanced System Longevity: By protecting the core electrical connections from moisture, corrosion, and physical stress, these connectors extend the operational life of the entire connected system, from sensors to actuators.

Design Flexibility: The availability of straight and right-angled versions, along with multiple cable types and lengths, gives design engineers the freedom to optimize machine layout and cable routing without compromising on performance.

Global Compliance & Quality: Manufactured to meet international standards for electrical components, ensuring compatibility and safety in global markets.

The versatility of the M8 4-pin connector makes it a preferred choice across a wide spectrum of industries.

Industrial Automation: Connecting sensors (proximity, photoelectric, pressure), actuators, solenoids, and small motors on assembly lines and robotic cells.

Factory Robotics & Robotic Arms: Providing power and control signals to end-effectors, grippers, and vision systems in collaborative and industrial robots.

LED Lighting Systems: Ideal for outdoor and industrial LED fixtures, including street lights, high-bay lighting, and architectural lighting, where IP65 protection is essential.

Process Control & Instrumentation: Interconnecting field devices, controllers, and measurement equipment in harsh plant environments.

Agricultural and Construction Machinery: Withstanding the vibration, dust, and moisture encountered in heavy equipment.

Transportation Systems: Used in railway and vehicle applications for sensor and control unit connections.

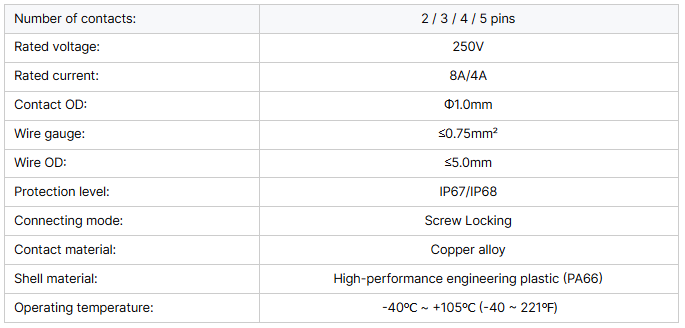

Q1: What is the voltage and current rating for this 4-Pin M8 connector?

A: Typically, our standard 4-pin M8 connectors are rated for 250V AC/DC and a current of up to 4A per pin. It is crucial to check the specific product datasheet for the exact ratings of the model you select.

Q2: Can this connector be used for Ethernet or PROFINET communication?

A: No, this 4-pin version is not designed for standard Ethernet protocols. Ethernet communication typically requires a dedicated 4-pin layout or an 8-pin M8 connector. This 4-pin model is best suited for power and standard signal transmission (e.g., 0-10V, 4-20mA).

Q3: How do I ensure the IP65 rating is maintained after assembly?

A: The IP65 rating is achieved with a properly assembled connector. Ensure the cable gland is correctly tightened onto the cable outer jacket, and the rubber seal inside the gland is intact. For panel-mounted female connectors, ensure the integrated O-ring is clean and properly seated against the mounting surface.

Q4: What is the difference between PVC and PUR cable jackets?

A: PVC (Polyvinyl Chloride) is a general-purpose, flexible, and cost-effective material with good durability. PUR (Polyurethane) is more premium, offering significantly better resistance to oils, chemicals, abrasion, and repeated flexing, making it ideal for highly demanding automated environments.

Q5: Are these connectors available with pre-wired cables?

A: Yes. We offer these M8 connectors as cord sets (pre-wired male and female connectors) in various standard lengths, which can significantly reduce installation time and ensure consistent, factory-quality terminations.

Q6: What tooling is required for field assembly?

A: Assembly typically requires a standard wire stripper and a screwdriver. A dedicated crimping tool is recommended for attaching the pin contacts to the wire conductors for a perfect, reliable termination.

Contact person: Mr. Bei

Mobile phone: +86 13378428166

whatsApp: +86 13378428166

Address:2F, Bldg B, Guancheng High-Tech Industrial Park,

No. 2, Xiguangyue 1st Road, Xinhu Street,

Guangming District, Shenzhen, 518107

Copyright © 2025 Shenzhen Jiayunkang Technology Co., Ltd. All Rights Reserved. support: huaqi

This website uses cookies to ensure you get the best experience on our website.