Product Description

The M15 Injection Molded Waterproof Connector represents the next generation of industrial connectivity solutions, specifically engineered for extreme environmental conditions. Utilizing advanced injection molding technology, this connector achieves exceptional sealing performance and structural integrity that surpasses traditional manufacturing methods. The precision molding process ensures perfect consistency in every unit, eliminating potential failure points and delivering unmatched reliability in wet, dusty, and corrosive environments. With its IP68 rating (submersible up to 1.5 meters for 24 hours), this connector provides superior protection where standard waterproof connectors fail. The innovative contact design maintains stable electrical performance even under thermal cycling and mechanical stress, making it an ideal choice for critical applications where connection failure is not an option.

Product parameters

Cable name :M15 Waterproof Connector

Plug specification: Inquire with customer service

Wire specification: Customizable

Wire length: Inquire with customer service

Cable sheath :PVE

For more detailed inquiries, please contact our customer service!

Product Features

Advanced Injection Molding Technology

The connector body is manufactured using high-pressure injection molding with fiber-reinforced PBT material, creating a monolithic structure without seams or joints that could compromise waterproof integrity. This process ensures dimensional stability and consistent performance across all production batches.

Superior Sealing System

Features triple-sealing protection: primary silicone O-ring seal, secondary housing seal, and internal potting compound protection. The multi-layered approach guarantees complete environmental protection even under pressure differentials.

High-Performance Contact Design

The contacts employ a dual-beam design with gold-over-nickel plating, providing low and stable contact resistance (<3mΩ) while ensuring gas-tight connections that prevent oxidation and corrosion.

Enhanced Strain Relief

The overmolded cable entry provides 360° strain relief and cable retention, distributing mechanical stress evenly and preventing cable pull-out even in high-vibration environments.

Quick-Lock Coupling Mechanism

The bayonet-style coupling system provides secure mating with positive tactile feedback, ensuring proper engagement while allowing for quick connection and disconnection.

Polarization and Keying

Available with various polarization options to prevent mismating in multi-connector systems, reducing installation errors and equipment damage.

Product Advantages

Unmatched Reliability

The injection molded construction eliminates traditional failure points, providing 3x longer service life compared to standard assembled connectors in harsh environments.

Reduced Total Cost of Ownership

Exceptional durability and reliability significantly reduce maintenance costs, downtime, and replacement expenses, delivering superior value over the product lifecycle.

Installation Efficiency

The quick-lock coupling system reduces installation time by 40% compared to Threaded Connectors, while the clear polarization prevents mating errors.

Performance Consistency

Precision manufacturing ensures every connector meets identical performance standards, eliminating quality variations and ensuring predictable system performance.

Environmental Adaptability

The extended temperature range and chemical resistance allow deployment in the most challenging environments, from arctic conditions to chemical processing plants.

Application Fields

Industrial Automation

Robotic systems and manipulators

CNC machinery and tooling equipment

Assembly line automation systems

Material handling equipment

Outdoor Infrastructure

Traffic control systems

Street lighting networks

Surveillance and security systems

Public transportation equipment

Marine and Offshore

Navigation system connections

Deck equipment instrumentation

Underwater sensor arrays

Marine communication systems

Energy Sector

Wind turbine control systems

Solar power installations

Oil and gas field equipment

Power distribution systems

Transportation

Railway signaling equipment

Heavy vehicle electrical systems

Airport ground support equipment

Electric vehicle charging systems

Frequently Asked Questions (FAQ)

Q1: How does injection molding improve waterproof performance?

A: Injection molding creates a seamless, monolithic structure without joints or seams that could leak. This eliminates potential failure points and ensures consistent IP68 protection throughout the product lifecycle.

Q2: What is the difference between IP67 and IP68 ratings?

A: IP67 provides protection against temporary immersion (1 meter for 30 minutes), while IP68 offers continuous submersion protection (1.5 meters for 24 hours in our specification).

Q3: Can the connector withstand high-pressure washdowns?

A: Yes, the connector is designed to withstand high-pressure cleaning (up to 1000 psi) and steam cleaning procedures commonly used in food processing and pharmaceutical industries.

Q4: Are custom cable lengths available?

A: We offer complete customization options including cable length, jacket material, and connector configuration to meet specific application requirements.

Q5: What is the expected service life?

A: The connector is rated for minimum 500 mating cycles while maintaining its waterproof integrity, with an expected service life of 10+ years in harsh environments.

Q6: Is the connector compatible with existing M15 systems?

A: Yes, it maintains standard M15 dimensions and mating interface while offering enhanced performance features.

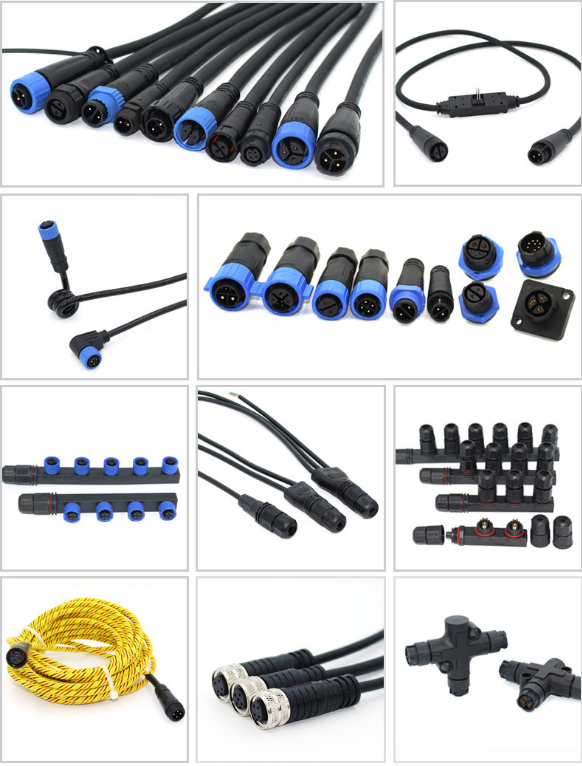

Display of waterproof plug

Contact person: Mr. Bei

Mobile phone: +86 13378428166

whatsApp: +86 13378428166

Address:2F, Bldg B, Guancheng High-Tech Industrial Park,

No. 2, Xiguangyue 1st Road, Xinhu Street,

Guangming District, Shenzhen, 518107

Copyright © 2025 Shenzhen Jiayunkang Technology Co., Ltd. All Rights Reserved. support: huaqi

This website uses cookies to ensure you get the best experience on our website.